A multitude of options combined with ever decreasing time and human resources: By presenting concrete solutions relating to the focus topic of “easy” automation at the Hannover Messe (Hall 17, Stand B50), Yaskawa will demonstrate how companies caught up in the midst of Industry 4.0 complexity can benefit from consistently easy-to-use components.

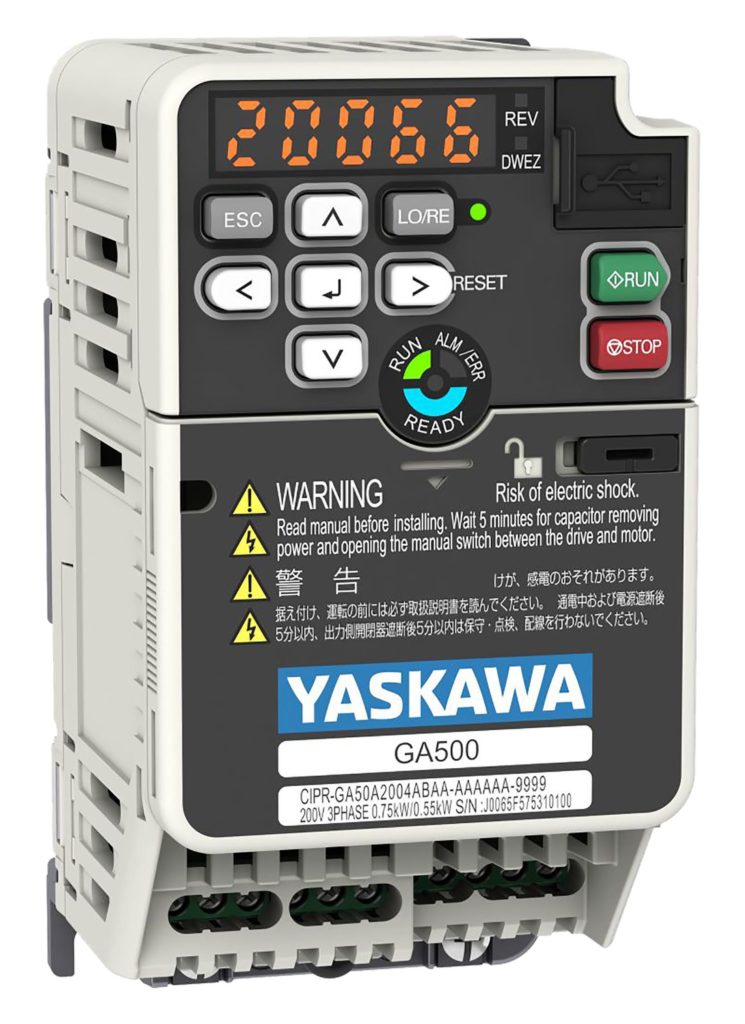

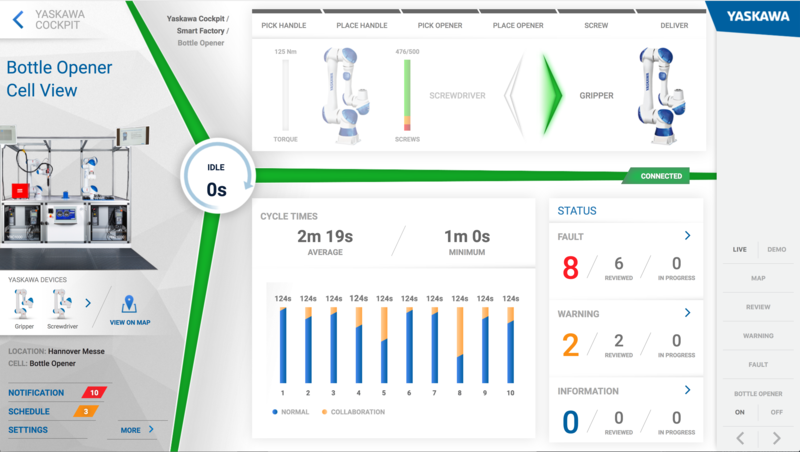

Easy programmability, rapid start-up and optimal operability are at the forefront of recent developments in drive technology and robotics. This is clearly demonstrated by the new GA500 inverter drive, which celebrates its world premiere in Hanover, and the i3 mechatronics solution YASKAWA Cockpit, which will be available to customers in an enhanced Edition 1 version from summer 2019 onward.

The GA500 is a new and particularly compact addition to the current generation of inverter drives and is ideal for industrial applications: The easy-to-handle inverter offers 800 parameters and, with its extensive range of functions, can provide the ideal solution for almost every drive application. Despite its versatility, it can be easily configured by answering five minutes of simple questions. In industrial production, the ease of use not only greatly simplifies the commissioning process but also significantly shortens it. In addition, the GA500 is suitable for all motor types, including permanent magnet motors.

A live demonstration from the Yaskawa stand based on a project carried out by the Hans-Dietrich-Genscher-School (HDG) in Wachtberg near Bonn demonstrates the importance of simple programming and operation when using industrial robots — a topic which is all the more relevant given the recent introduction of the Digital Pact program in schools. With its “HDG robotic 4.0” project supported by Yaskawa, the renowned interdenominational secondary modern school is breaking new ground in the teaching of digitization and technological expertise: The educational program prepares schoolchildren in grades 7 to 9 for digitization and provides key skills in the programming and control of micro-controllers and robots.

The i3 mechatronics solution YASKAWA Cockpit, which made its debut at the last Hannover Messe, will also make an appearance in 2019, as an enhanced Edition 1 version of the software will be available to customers from summer 2019 onward. Using this platform, data from components, robots or entire systems, including products from third-party suppliers, can be recorded in real time and the information generated can be displayed and evaluated in a visually appealing, comprehensible and meaningful way.

The fact that robotics plays such an important role in achieving simple and flexible automation is clearly demonstrated in Yaskawa’s numerous robotic exhibits. The showcased solutions range from machine feeding systems and collaborative robots—some mobile and some mounted on an AGV (automated guided vehicle system)—to a collection of planned products from Yaskawa’s first European robotics production run. Visitors can also look forward to a prototype of the new and larger collaborative robot Motoman HC20.

Yaskawa’s Environmental Energy Division (EED), which specializes in wind, marine and industrial turbo applications, is launching a new turbo electric motor for power ranges from 100 to 600 kW. Unlike the classic solution, this new innovation achieves the required high speeds of 6000 to 21,000 rpm without additional gear units. Compared to conventional solutions with gear units, this results in significant advantages in terms of compactness and longevity: The gearless turbo motor requires 50 percent less space and, at the same time, is much less maintenance-intensive because it consists of fewer components.

The GA500, which celebrates its world premiere in Hanover, is a new and particularly compact addition to the current generation of inverter drives and is ideal for industrial applications. Source: Yaskawa

The i3 mechatronics solution YASKAWA Cockpit, which made its debut at the last Hannover Messe, will be available to customers as an enhanced Edition 1 version from summer 2019 onward. Source: Yaskawa