We started out in the wind business in 2006. Back then, top turbine manufacturers were rapidly adopting permanent magnet (PM) machines, which were more efficient, reliable and dependable than the other technology options on the market.

Moreover, the value chain was simple, and the generator/drive supplier dealt directly with the OEM and no one else. Selling the technology was straightforward, and today 80% of the top turbine manufacturers use PM generators.

The marine business, however, is more conservative and complex. Component suppliers, system integrators, shipyards, and shipowners – often from different continents, time zones, and working cultures – present a myriad of challenges. Orchestrating their efforts and convincing the historically conventional stakeholders of the superiority of PM technology is challenging.

What’s more, classification agencies, such as DNV-GL, Lloyd’s Register, and ABS, must review and approve the ship’s main components so shipowners are eligible for insurance. As conventional electric machine types have been used for more than 100 years, consequently the rules have been written according to these devices.

Meeting extremely strict standards

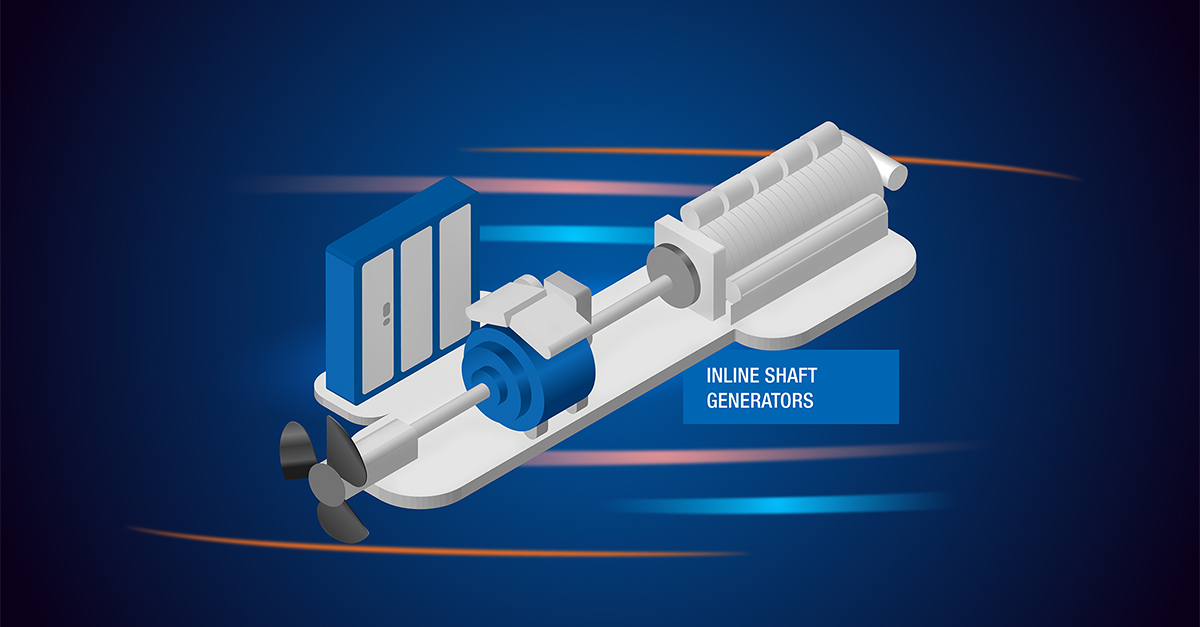

Around seven years ago, when we started in the marine business selling PM shaft generator units, we had to comply with classification agency requirements, which weren’t easy to interpret relative to PM machines. To adopt, we established connections with specialists at the classification agencies who explained the rules and helped us address the specific requirements for PM technology. Soon, we were getting stamps of approval following factory acceptance tests – witnessed by a system integrator, the shipowner, and a representative from the classification agency.

Today, the process for approving PM machines is simpler and more straightforward, if still demanding. For example, if there is only one propulsion line, then the classification societies have some additional requirements in case a PM shaft generator is used. Compared with conventional machines, PM machines have a magnetic field that cannot be switched off if there’s a problem. To get approval from classification societies, you must be able to mechanically disconnect the PM machine rotor from the propeller shaft and switch to a redundant system. Without this ability, if there’s an electrical fault, the whole system has to be shut down, leaving the vessel drifting in the sea due to a lack of a redundant propulsion line. To address this issue, we’ve developed a special hydraulically operated coupling between the PM machine rotor and propeller shaft, which can be opened rapidly, if needed.

Advantages outweigh the challenges

Despite these challenges, the shipping industry has started to embrace PM technology more and more to deal with fluctuating fuel prices and tightening emission regulations. Shipowners stand to save up to €1 million over the lifetime of a vessel with a 2 MW PM shaft generator system compared with a conventional generator.

And they can reduce CO2 emissions by up to 200 tons in a single year or 4,000 tons during the lifetime of the vessel. PM machines also provide a more reliable system that needs less maintenance as a result of simpler construction.

Therefore, shipowners and shipyards are adopting PM technology more now than ever before for power generation and propulsion systems.

And, more importantly, advanced PM machine designs with added safety features are increasing the overall safety of the marine industry.

Dr. Jussi Puranen