In 2020, we launched our SRS standalone high-speed machine and the “no gear” marketing campaign. We wanted to show customers who need high rotational speed that we provide an attractive possibility to remove the complicated, low-efficiency and expensive mechanical gear from their systems.

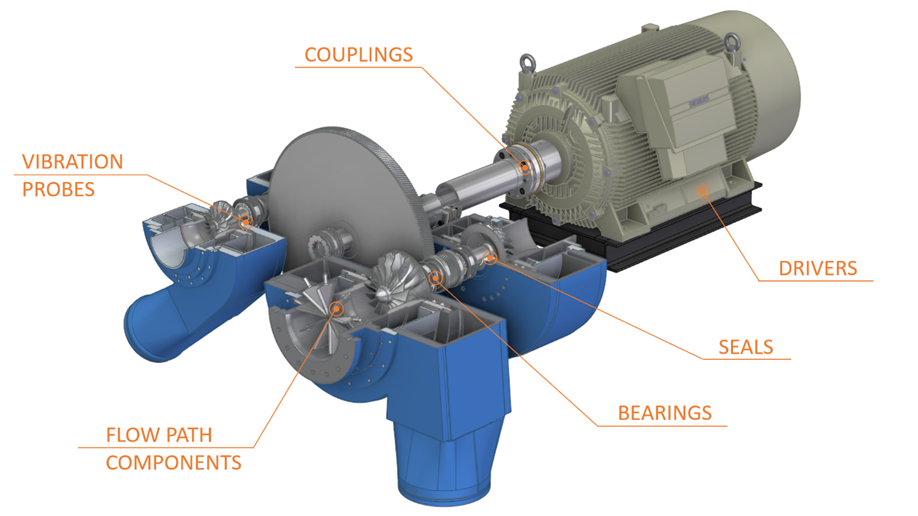

Now in 2023, there seems to be push for even further with demand for a complete integration of the electric machine in the application. Therefore, the final product – usually a compressor or high-speed blower – becomes a motor-compressor instead of traditional drive train with a compressor, gear, coupling and electric machine. An example of such a drive train is shown below.

An example of such a drive train is shown below.

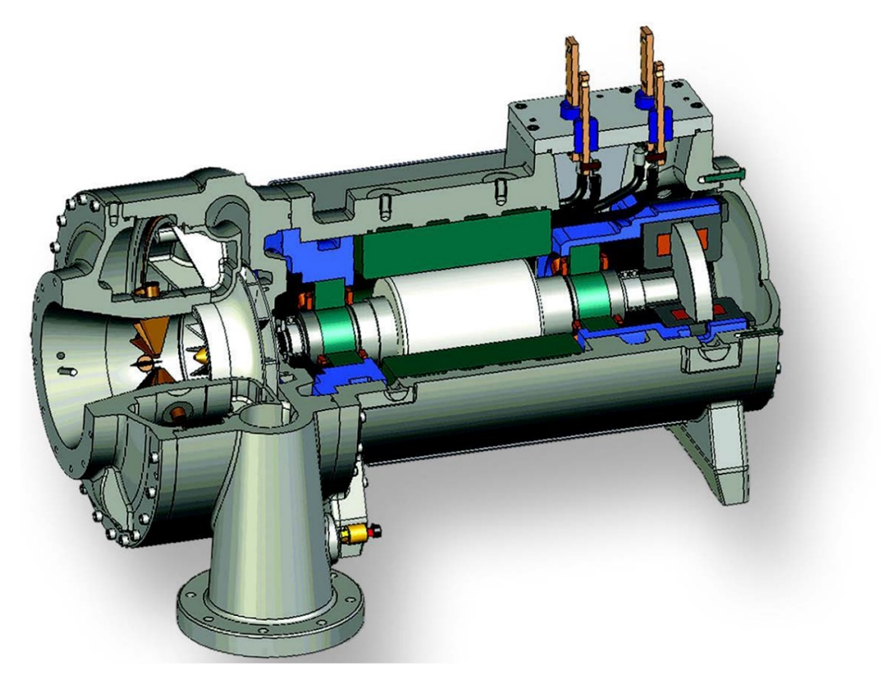

- Rotating seals are removed. No more wear or leaks. Everything visible to the outside consists of static parts only.

- Compressed media can also be allowed within the electric machine when everything is inside a hermetic casing. Cooling of electric components can be improved with compressed media compared to typical air cooling.

- Fewer bearings, no coupling. When the whole drive train consists of a single rotor supported by two bearings, installation of the machinery is straightforward, and manual alignment of machines is not needed.

- Active magnetic bearings (AMBs) levitate the rotor. Without physical contact, there is no need for lubrication, and the bearings will never require replacement or other maintenance. Additionally, most speed and load limitations of ball bearings or sleeve bearings are removed.

So, we are seeing machines that are more sophisticated, compact and economical to operate, while having higher performance capabilities with fewer components and lower maintenance needs.

An example of a motor-compressor with AMBs is shown below.

Often these fully integrated machines are quite challenging to design. The high-speed centrifugal compressors are intended for various applications. The media being compressed can be clear air, carbon dioxide, exotic refrigerants or natural gas, for example.

Our electric machine parts have to tolerate the media as it simultaneously flows through the stator and rotor, keeping temperatures under control. Such material compatibility information is not readily available, and we must perform material testing at third-party laboratories to ensure a long lifetime for our components.

Getting the single rotor approach working will also require a major study of the bearing and rotor-dynamic performance. Active magnetic bearings, which are really just electric machines with a stator, rotor and position sensor, will need to be engineered for the specific motor-compressor to ensure sufficient load capacity and rotor control.

Fitting all these pieces together with the customer initially is a puzzle where nothing is initially fixed. Apart from technical challenges, the greatest difficulty may be to justify the significant initial investment in developing a completely new product with the parties involved.

Another crucial matter is to ensure a dependable component supply chain. Integrated machine components are not as easy to replace by a third-party vendor compared to those for traditional drive trains.

Still for some time, we have been demonstrating our advanced solutions and presence in this field. The benefits presented above are simply too attractive to ignore.

Product Manager, Solid Rotor Machines

Panu Hava

Panu Hava currently works as Product Manager, solid-rotor machines at The Switch. He has over a decade of experience in product development of electric machines, including industrial induction and synchronous machines as well as high-speed induction machines. Today, his main responsibilities are technical sales support for new tailored products and leading product development of high-speed electric machines. Hava holds a M.Sc. (Tech.) in Mechanical Engineering from Lappeenranta University of Technology.