People always say that you have to look forward in order to succeed. Still, it’s sometimes good to look back as well to see where you’ve come from.

Recently, I received a visit request from a group of people who wanted to know how The Switch got where we are today. So, I had to think back over our history.

My involvement traces back to being Associate Professor Pyrhönen’s first assistant. But let’s start from the beginning!

Origins of high-speed machines

In the late 1980s, the father of The Switch solid-rotor machines, Juha Pyrhönen, wrote his doctoral thesis at LUT University in Lappeenranta. Titled “The High-Speed Induction Motor: Calculating the Effects of Solid-Rotor Material on Machine Characteristics,” this work laid the foundation for advancements in high-speed technology.

There were also some other activities in this field in Lappeenranta. For instance, the compressor from High Speed Tech Oy featuring the motor designed by TKK in Otaniemi. Interestingly, some of the things designed back then are still being used today in our machines.

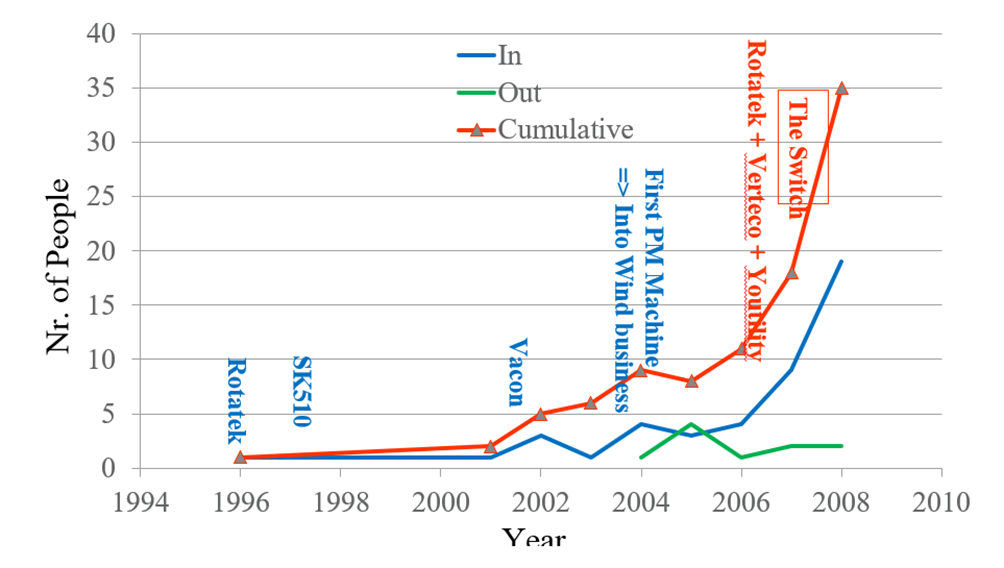

In 1996, Jarmo Alamäki from High Speed Tech decided to start up his own business. Looking for technology to use, he came across Pyrhönen’s LUT research. That was the start of Rotatek Finland Oy.

First applications

The first motor compressor from Rotatek was delivered to the Lappeenranta wastewater treatment plant to work as an aeration compressor for oxidizing the wastewater.

Some high-speed technology developments had also been carried out for Ecopump Oy (today, Runtech Systems Oy) – initially, without major success. The idea was to apply solid-rotor technology to Ecopump’s vacuum compressor. Only after numerous trials, the technology seemed to be working. Originally designed for 150 kW, the machine was finally able to produce 250 kW. Today, this frame is up to 315 kW.

Seeking support to drive expansion

In 2000, concerns were raised about the company’s ability to expand with Alamäki’s individual efforts. In response, a few university personnel, including me, along with a couple of companies, proposed acquiring a majority share of Rotatek to help the business financially and technically. Quite soon, we realized that our financial, technical and labor contributions were still not enough to accelerate the business.

The search for wider shoulders started in 2001. That’s when Vacon and J-P Mäkinen came into the picture. The prior integration of Vacon inverters into our motor drives had already proven beneficial for us. This time, Vacon brought forth other valuable resources, especially in terms of financing and marketing.

By 2002, there were four people working for Rotatek. Our only product was the solid-rotor motor, and Ecopump was practically the only customer.

Responding to market needs

In 2003, Verteco was founded in Vaasa as a spinoff of Vacon. The goal of the company was to implement Vacon inverters in wind power applications.

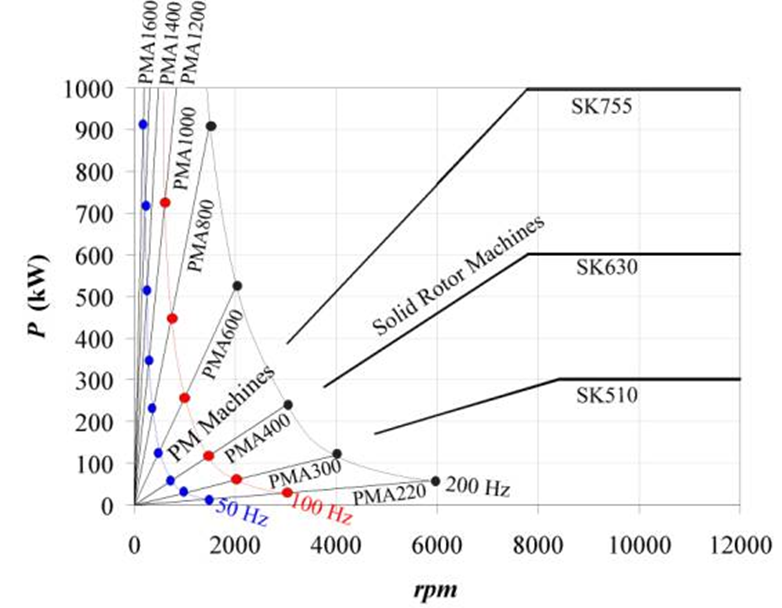

At around the same time, we at Rotatek decided to launch another product family – permanent magnet machines. This expansion allowed our offering to cover the whole range from low speeds to 12,000 rpm and powers reaching up to one megawatt. Still, we did not plan to compete with standard induction motors.

The significant turning point occurred in 2004. VNT Management, the major shareholder of Verteco, became also the major shareholder of Rotatek. This marked the start of a partnership between Verteco and Rotatek. It also marked the beginning of our venture into the wind energy sector with our machines.

Negotiations with Norwegian wind turbine manufacturer ScanWind followed. For Rotatek, this meant a huge leap in both business volume and machine size.

The same year, MAN was looking for a motor technology partner for their gas compressor development project. Their consultant happened to know J-P Mäkinen well, and this is how our paths crossed. They were convinced that Rotatek – a five-person spinoff – could be the right strategic partner for a world-class company. And they were right! The cooperation between the companies continues to this day.

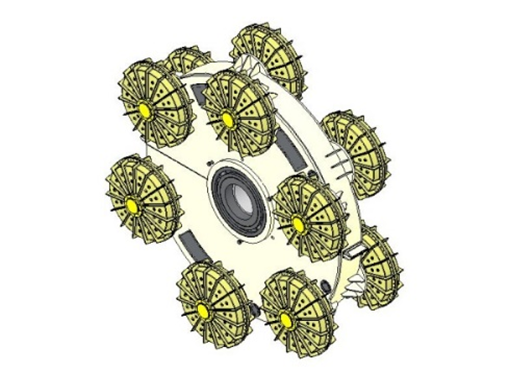

The leap in technology required a lot of new ideas and innovations. In 2005, Rotatek was #13 for the number of patent applications submitted in Finland. We had a multitude of ideas, even if they were not always the most feasible. One of these was a scalable multigenerator, a vision where a single-gear wheel serves as the foundation, and additional machines can be seamlessly added around the circumference.

The Switch is born

Another player without whom The Switch story wouldn’t be complete is Youtility. Founded in 1998 in the USA, Youtility specialized in power electronics for solar cells, fuel cells and variable-speed genset control. In its most active years, the company had 10 employees. As the solar business was not that big a success, the unit slowly shrank and got integrated within Yaskawa US.

Down the line, the three companies, Rotatek, Verteco and Youtility, all had the same major shareholders – Vacon, VNT management and Semicron – and the business related to energy efficiency and new power solutions. Therefore, the owners decided it makes sense to put them under the same umbrella. And so, The Switch was established in November 2006.

Through ups and downs

For The Switch, the biggest financial breakthrough happened in 2007 when our business took off in China with companies such as Goldwind. Suddenly, a company of some ten people became a company with around a hundred employees, a global organization and a rapidly growing turnover. Even the 2008 global recession did not hit us badly, given that the majority of our business was sustained by operations in China.

However, nothing lasts forever. A change came in 2011. The Chinese wind market had gone wild. Because of available subsidies, turbines had even been built in areas where the grid was not available. However, our Chinese wind power business was almost completely put on hold. In a matter of months, the price of rare earth materials surged by around 600%. These materials are the core components in high-energy-density permanent magnets used in our machines. The sudden increase scared many industry players, leading some to transition back to old-fashioned double-fed technology, unable to withstand grid faults and causing large blackouts.

Luckily for us, another big sales wave came with the 8 MW turbine generator for Vestas. As always, the path from the first discussions in 2011 to volume production took about four years.

New horizons and acknowledgments

At some point, The Switch also stirred up a different kind of interest. In 2014, one of the world’s leading manufacturers in the field of drive technology, Yaskawa, acquired the company. Being part of the corporation’s Environmental Energy Division (EED) proved to be a valuable experience for us.

All this would not have happened without the support of our valued investors. I can’t emphasize enough the role of Veijo Karppinen, the former CEO of Vacon and one of the VNT Management founders. Without his commitment and belief in our team, I wouldn’t be here writing this story. And just as important are the management and personnel teams we have had at the company during all these years!

Today, we’re looking forward to even more exciting times ahead of us!

VP Technology

Panu Kurronen

Dr. (El.eng.) Panu Kurronen is Vice President, Technology, at The Switch in Lappeenranta, Finland. Prior to joining the company at its very start, Panu worked as a technical manager at Rotatek Finland Oy, one of the three companies that initially merged to form The Switch in 2006. Panu graduated as a Doctor of Science (El.eng.) from Lappeenranta University of Technology in 2003. Over the years, he has worked as a researcher, laboratory manager and associate professor at Lappeenranta University of Technology. From 1995 to 2000, Panu worked as project manager at Kone Elevators. His focus has always been on the application of permanent magnet technology.