In 2018, the offshore wind market grew by 0.5% to 4.49 GW of new installations, and the total installed wind capacity saw an increase of 9.6% compared to the end of 2017. Wind power being now regarded by many as the cheapest way to build energy capacity has also had a positive effect on our ongoing production efforts.

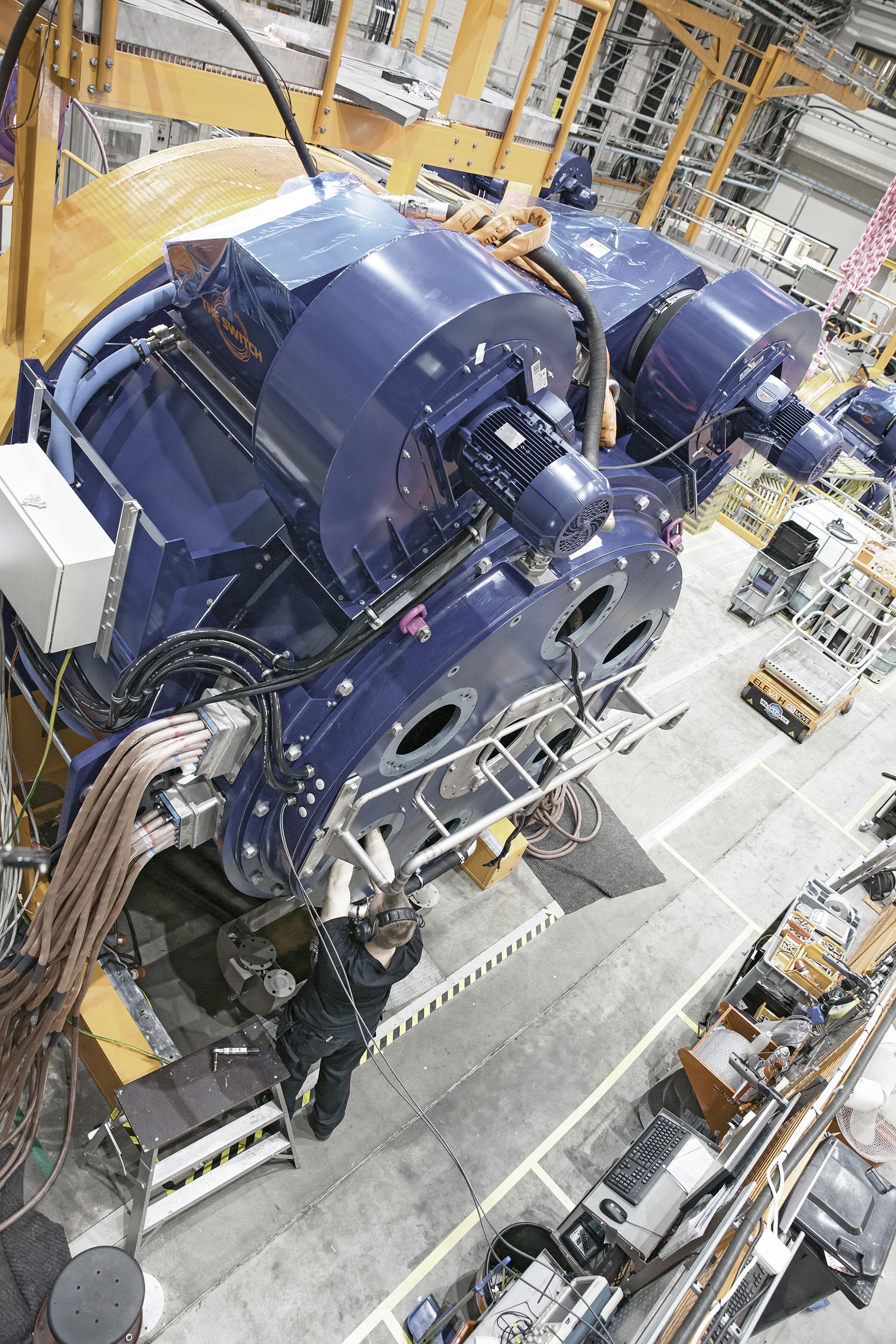

Since 2015, we have undergone serial production of our PMM 1500 permanent magnet generators for offshore wind turbines. As of now, we have manufactured, tested and delivered over 300 of these machines with great success.

Looking back at our production numbers from the last few years, we had doubled our annual production output in the first three years, and our current production rate from June 2019 to July 2020 is estimated to be around 170 permanent magnet generators.

The rise in production is not only a positive for us, but also reflects the ongoing growth of the wind industry. By increasing our annual production rates, we have been able to keep up with the industry’s growing needs for advanced power generation technology, lower costs of energy production and improved system efficiency.

Our machine deliveries have also been on point despite some small hiccups along the way. Getting the right materials with production deadlines around the corner is a common challenge for many companies. However, we have always been prepared for these kinds of challenges by having an extensive supplier network for our components. This way we can ensure that the high-quality components we need to make top-of-the-line permanent magnet machines are always available.

When manufacturing these products, the quality of our machines is paramount. Maintenance work in offshore wind turbines is extremely expensive, which means that our products have to be flawless when being shipped to the customer. We always undergo extensive testing in our Vaasa factories in the form of full-power and routine tests to ensure that on-site maintenance work is held to a minimum. Despite all this, there is always room for improvement in terms of quality and optimizing manufacturing costs, and we are doing our best to always keep improving and fine-tuning our operations.

During the past year, we have taken measures to increase our capacity, not only in terms of our supply chain, but also at our own factory in Vaasa. A new, second rotor assembly line, in addition to the one located currently at our Lappeenranta factory, will be introduced to our Vaasa factory to help respond to the increased capacity demand. This addition allows us to have the assemblies in a centralized location and make our manufacturing more efficient. Furthermore, our upcoming factory expansion in Lappeenranta will allow us to assemble and test these machines there in the future, too.

We look at the future of the wind business with great excitement. We will continue making high-quality permanent magnet generators to support the growth of the wind industry and clean energy, by increasing the turbines’ annual energy production and minimizing the total life-cycle costs.

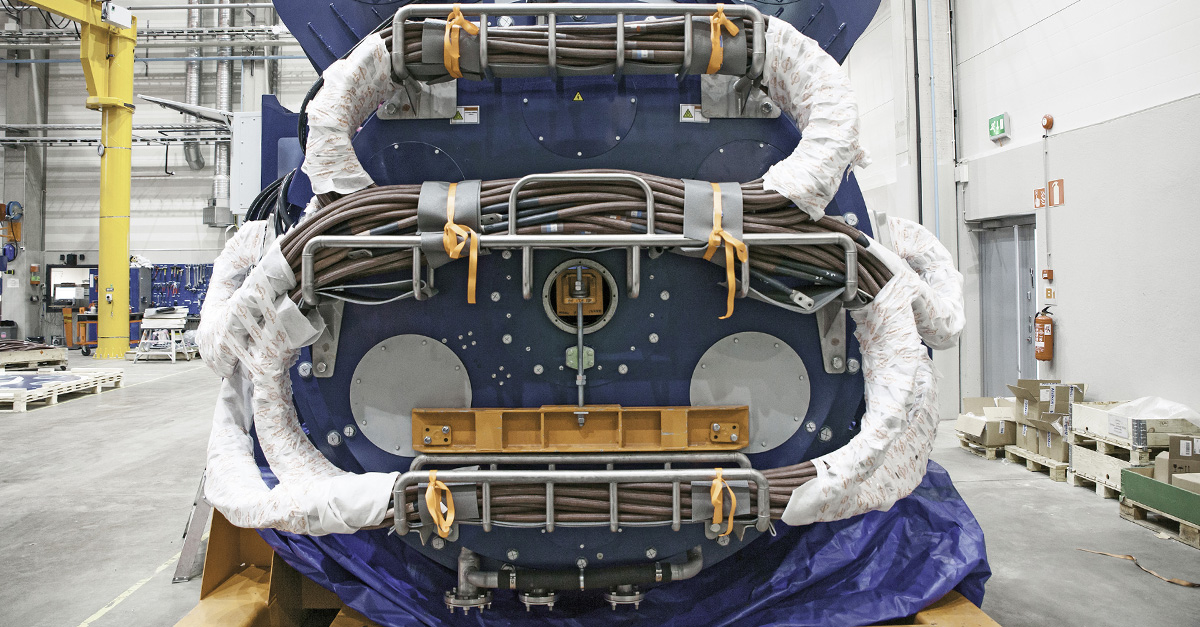

The Switch PMM1500. We have manufactured, tested and delivered over 300 of these machines with great success.

The Switch PMM1500. We have manufactured, tested and delivered over 300 of these machines with great success.