Think outside the gearbox with solid rotor technology

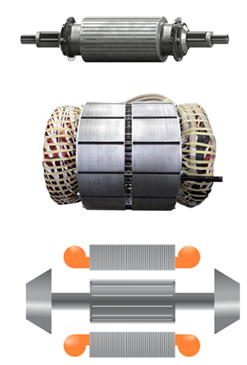

Our direct-drive, high-speed induction machines allow you to eliminate the mechanical gearbox, allowing you to reach higher speeds and unmatched energy efficiency.

Solid-rotor technology extends the speed capabilities of standard induction electric motors, answering the demand for high-speed motors when running below multi-megawatt powers.

0 rotor failures in over 10 years of industrial operation

Power range from 300 kW – 2 MW

Speeds up to 20,000 rpm

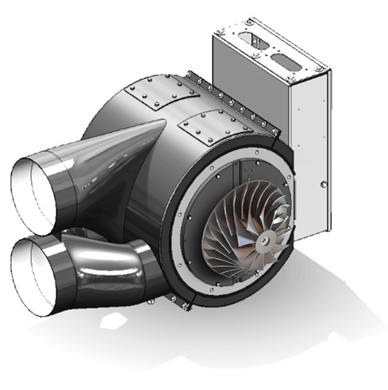

Our high-speed products are ideal for applications, such as blowers, compressors, pumps, vacuum systems and other industrial applications in the speed range of 6,000 – 20,000 rpm. Additionally, our customers have used these motors in various test-bench configurations. We are also willing to discuss projects involving multi-megawatt hermetically sealed and hydrogen compressors.

High-speed induction machines

Our standalone product range comes in two frame sizes – 315 and 400. The high-speed machines are designed to be coupled to driving or driven machinery through a separate coupling, for example a steel pack coupling.

Semi-integrated solutions

Semi-integrated machines include the compressor, turbine or pump impeller mounted directly on the shaft of the electric machine. The bearing system and rotor dynamics can be calculated and tailored to the application.

Semi-integrated solutions are available based on our successful long-term joint development projects with world leaders. Ask us more!

Fully integrated solutions

For ultimate system simplicity, we can offer integrated machines. Active parts of the solid-rotor machine can be completely tailored to suit different applications. We are happy to discuss the delivery scope case-by-case.

Fully integrated solutions are available based on our successful long-term joint development projects with world leaders. Ask us more!

Whitepaper Download

The design of an electric motor for a heat pump

application requires close cooperation between the heat

pump process design and electric motor design – and

many compromises need to be made.